Food that has been frozen is a food product that has been kept at a low temperature and is long-lasting. By reducing the temperature to prevent the growth of microbes, freezing is a method of preserving food in the frozen food processing industry. A variety of diverse food options on the market, including prepared meals. Snacks, desserts, and packaged ready-to-eat items are all included in frozen-ready meals.

For producers to improve frozen food processing, system integration is required. The manufacture of frozen foods requires efficient communication across all components to make it an effective system. The target market for this industry is hence substantial.

The preparation of frozen food can be accomplished using a range of methods, including the infusion of cold air. Air-blast freezing encompasses a variety of procedures. Some ways expose the food product to a free-flowing stream of -30°F freezing air using fluidized beds, tubes, or belts. This method enables the production of precisely fast-frozen product bits. To prevent dehydration and the transmission of product moisture to the surfaces and/or cooling coils, special caution must be used.

Cryogenic freezing is an additional option that has recently gained popularity. Food items are sprayed with gas liquefaction solutions that have been incredibly chilled, such as liquid nitrogen or carbon dioxide. This method is typically employed by small businesses, notably during the initial stages of product processing. Furthermore, in cryogenic freezers, damp or otherwise sensitive goods are swiftly crust-frozen so they can be handled in an interface or air-flow freezers afterward.

Packaging of Frozen foods

The primary goal of packaging is to safeguard a product from potential physical, chemical, and biological risks. Due to the growing demand for frozen foods, it also serves a number of additional functions such as making product handling and transportation much simpler, assisting easier storage and stackability, diminishing available space, delivering information to customers, improving product appearance and consumer appeal, and promoting and announcing brands, among others.

Frozen Food is packaged in one of three ways:

Primary, Secondary, or Tertiary.

1. Primary Packaging: The food comes into direct touch with the primary packaging. Until the time of usage, the food is kept inside the package.

2. Secondary Packaging: A type of multilayer packaging used to handle products in combination for sales purposes is known as secondary packaging.

3. Tertiary Packaging: To maintain quality and freshness during transporting these goods demands the usage of tertiary packing.

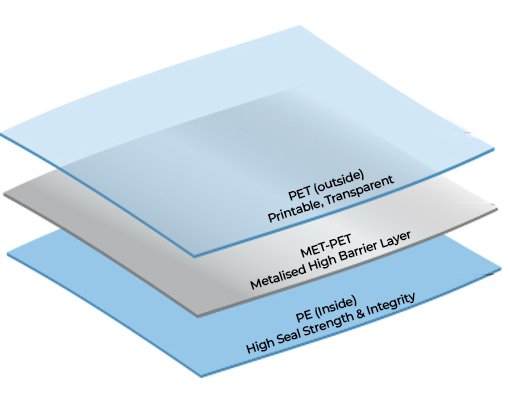

- To keep the maximum quality of frozen foods, packaging materials such as glass and stiff plastic should be moisture-vapor-resistant/moisture barrier bags.

- To keep out moisture and oxygen, hermetic packaging must be done with a vacuum or gas-flush system.

- The majority of bags, wrapping supplies, and waxed cartons used to package frozen foods are resistant to moisture and vapor.

- The containers ought to be simple to seal and leak-free.

- Another crucial element is the material’s durability since packaging must resist becoming fragile and cracking at low temperatures.

- Glass, plastic, tin, and other cardboard materials that have been extensively waxed are rigid containers that are utilized to package liquid food goods.

- Bags and sheets composed of thick, moisture-free aluminum foil, polyethylene, or laminated papers are instances of non-rigid containers.

The characteristics of frozen food packaging

The following aspects must be included in frozen food packaging:

- For as long as the commodity has a shelf life, it should be able to survive temperatures below zero. At low temperatures, some materials become weak and delicate.

- Should not leak its contents or flavors into food, and it should be composed of food-grade materials.

- Water vapors shouldn’t be capable of passing through it. Food containing a lot of moisture shouldn’t be dealt with porous materials since the product will quickly get dehydrated.

- To retain the product and safeguard it from the physical challenges of handling, transit, loading, unloading, and shelf pressures, the shelf should have better mechanical strength.

- Fragrance penetration: The packaging material must be able to prevent aromatic components in food from dissipating or decaying.

- Food that is packaged for shelf life must be securely sealed inside the pack. As a result, packing materials need to have high sealing abilities.

- To carry out labeling requirements, it should be printed.

- Aseptic procedures shouldn’t themselves be a source of food contamination.

- Food should be covered from sunlight exposure since the UV and infrared rays of the sun have a deteriorating effect on food.

Basic Tenets for Packaging Frozen Foods

The following packaging specifications must be adhered to by manufacturers of frozen foods:

- Client appeal

- Safety of food

- Resisting tampering

- Absence of leakage

- Impermeability

- Longevity

- Enables rapid freezing

- Resistance to temperatures of -40 °F

- Eco-friendliness

Key Take Away:

You should now be familiar with the entire frozen food processing method, from preparation to packaging. For some excellent frozen meal options topped with ace packaging, check out Goeld.